H-13 Sealer - Trinic

Trinic H13 - Sealer

View the application video below and upload Technical Data Sheet.

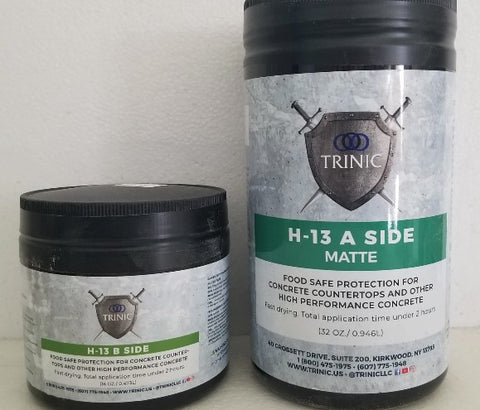

H-13 is enhanced for easy application, fast turnaround and represents a new generation of food safe protection for Concrete Countertops, and other high performance concrete. H-13 is a two component hybrid water based fast applying sealer with excellent stain, acid, and scratch resistance. H-13 is easy to repair if damaged and deeply penetrates concrete surfaces, forming a chemical bond to the concrete surface.

- Fast drying usually tack free in 15 minutes/ Total application time under 2 hours.

- Low sheen natural look with mild color enhancement of surface

- Excellent blush resistance in three days

- UV Stable, will not turn yellow.

- Excellent scratch, acid, and stain resistance in seven days

- Continues to build hardness out to 14 days.

- Re-coated by lightly sanding with 400-800 grit sandpaper and apply an additional coat

- Spot repair possible

- Can be used to repair other sealers.

Coverage

1.5 quart kit - 225 sq ft

Shelf LIife / Storage

Shelf Life: 1 year unopened and 3 months once opened

Storage: Keep in sealed container. We recommend using an inert gas filler such PolyPurge to keep the product fresh. DO NOT FREEZE

Tools Required.

- Accurate volumetric measuring utensils like syringes for small volumes and plastic mixing cups for larger amounts.

- Drill and paint stir attachment.

- 3/8 nap lint free microfiber roller

- Acetone

- Kitchen timer or cell phone timer.

- Polypurge, Bloxygen or other inert gas to prolong the life of the sealer after opening.

Mixing Instructions:

- Mix Ratio 2A:1B Stir Part A separately for 1 minute until it is smooth and uniform color and consistency.

- Add Part B side to Part A and slowly mix for another 2 minutes.

- Allow product to stand for 5 minutes.

- After 5 minutes’ induction time dilute the mixture with clean water. 1-part sealer with 1-part water (1:1). The water will thin out the sealer, so it lays out correctly and dries quicker. Once the water is added, the product is ready to use. Some people have successfully used a more diluted first coat 1-part sealer to 3 or 4 parts water with subsequent coats at 1:1. Kinda works like a primer and seems to allow for quicker subsequent coats.

- Working Time: The dilute sealer has a 60-minute pot life. Only mix enough material that can be used in 60 minutes. Change out roller after 60 minutes of use. Periodically remix any sealer that has sat for more than 10 mins to keep all ingredients in suspension.

Application Instructions:

- Professional use only.

- Pour the mixed material into a roller tray. Do not dip from a narrow container. For best results use a high quality 3/8 nap microfiber non-shed rollers.

- Use at least two microfiber rollers – One for rolling and spreading. Then second roller for finishing. The Finishing roller is used to take out any roller lines and remove excess material

- Spread material out thinly with 1st roller. Roll the same direction pulling the roller towards you. Move along the piece from left to right. When you reach end of the piece go back to where you started and roller again to spread the material out evenly.

- Then switch to 2nd roller to gradually roll out any roller lines with the finishing roller. Keep rolling in the same direction. When the rollers lines disappear STOP. Do not roll it dry.

- Allow each coat to dry a minimum of 15 minutes or until tack free and then repeat for subsequent coats.

- Do not allow H-13 to puddle in any joints. Make sure the room is well lit. This will help avoid missed spots when applying a clear sealer.

- Allow the surface to dry a minimum of 24 hours before moving the counter-top and wait 48 hrs. before exposing treated surface to water. Full cure is 7 days.

We Also Recommend